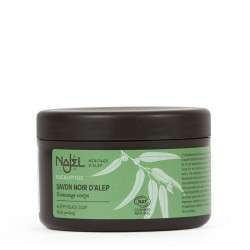

Aleppo Soap

Any product called Aleppo soap must be made in Aleppo, which is divided into 4 districts. Soap makers in Syria call their products ghar soap (laurel soap) if it is not made in Aleppo itself. We are fervent protectors of the traditional and ancestral know-how of Aleppo's master soapmakers. Our Aleppo soaps are authentic because they are really made in Aleppo according to the tribe's recipe.

Aleppo soap is protected by geographical indication under Syrian Law No. 8 Section 2 of 03/06/2007. A decree with a logo and a geographical indication was issued under No. 9134 on 10/05/2011. Geographical indication protection means that the name and location of manufacture are protected.

We call the making of Aleppo soap a "recipe" while considering the master soap makers who "cook" the soap.

In fact, the production of soap paste can be compared to a dish cooked in a kaldron.

Laboratoire Najjar has 2 production sites: a laboratory in France and the Al Najjar Soap Factory in Syria.

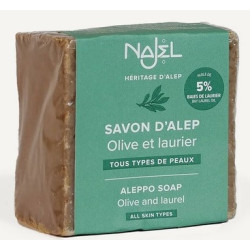

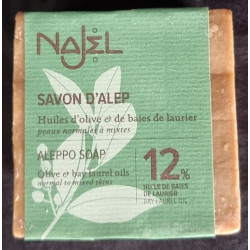

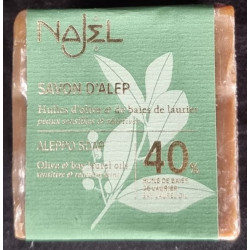

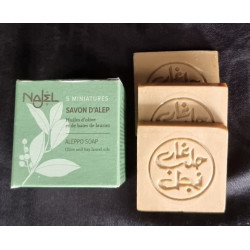

The family-owned soap factory is used for cooking, pouring and dry soap paste. These are the necessary steps for the traditional hard soap. In the soap factory there is also a storage area where the soap can dry for at least 9 months and for soap cleaning. A hand cut Aleppo soap is what we call traditional hard soap. They are also called Aleppo Soap Bread. These Aleppo soaps can be transformed (by adding an ingredient) and compressed (shaped) to enjoy Aleppo soaps scented with different perfumes for everyone.

The different stages in the production of Aleppo soap adhere to a traditional method that corresponds to a master recipe, which is fundamental to its quality:

Phase 1. Between late November and late March, the creation of the world's first hard soap follows the same, unchanged process. The saponification process begins by heating water and sodium hydroxide to a specific temperature in a large kaldron. We add olive oil, keep it at high temperature for 12 hours, then leave it. One of our main advantages is that we heat the paste by steam distillation, which allows us better control over the temperature. If the temperature gets too high, the oils lose their beneficial properties.

Phase 2. The next day we heat the contents of the kaldron while mixing them and the bay laurel oil (which has been filtered for the first time).

Phase 3. The resulting soap paste is then rinsed several times with salted water to remove a trace of caustic substances. The sodium chloride found in Aleppo soap is from this phase. The water is then removed from the Kaldron and recycled. These phases are part of the saponification process. The oil is converted into soap molecules through a natural chemical reaction between the oils and the sodium hydroxide.

Phase 4. Then the soap paste is spread out in a basin and smoothed on the surface. Once solidified, it is hand cut into soap. Each soap is then hand stamped with our Najel seal.

Phase 5. The soaps are then progressively lifted onto pallets and divided by percentage of Bay Laurel Oil before being placed in ventilated cellars, away from the sun. This marks the start of the minimum 9 month drying time. During this time, the soaps oxidize on the surface and turn a yellow/brown color while retaining an olive green color on the inside.

Phase 6. Once the drying period is over, the soaps are cleaned, filmed, closed and pallets tightened. They are ready to be shipped.